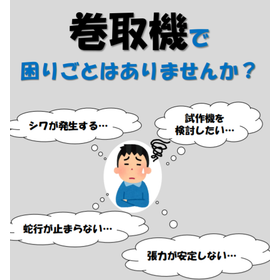

【Design・Customization】Winding Machine

Shortest half-day estimate / We only accept customization and modification design of equipment.

Dear Customer / Precision Machinery Parts Manufacturer, End User / Electronic Equipment Manufacturer, Request Details / Modification Design Using Existing Equipment Main Specifications Transport of small lithium-ion battery parts / Cutting from transport jigs Laser marking / Reel taping / Reel winding Device Dimensions / W3,500mm × D1,200mm × H1,000mm This time, we only accepted the mechanical and equipment design. We were responsible for the mechanical design of the work transport jig supply section, the cutting / retrieval / feeding section of the work, and the reel winding section. The customer handled parts procurement, assembly, and other aspects outside of mechanical design. We also accept projects that involve design only. We can flexibly respond to customer requests, whether for custom equipment or, as in this case, using existing equipment. Our greatest strength is our ability to provide a one-stop service for the entire process from design to installation in equipment and jig manufacturing. Please feel free to share any concerns you have regarding equipment and jigs, including robots, transport, and production facilities. From metal to plastic, we are ready to handle cutting and processing of prototype and development parts.

![Products equipped with high safety and technical features [electronic-related machinery] *custom-made!](https://image.mono.ipros.com/public/product/image/699/2000294900/IPROS3113250811879027063.jpg?w=280&h=280)

![Fuji Iron Works Co., Ltd. [Business Overview]](https://image.mono.ipros.com/public/product/image/6d9/2000366569/IPROS3061559797905907031.png?w=280&h=280)